This article was first published on the Save the Royal Navy website and republished here with their permission,

The Type 26 frigate is widely accepted as the best anti-submarine warship design available in the world right now. The quiet propulsion system that limits noise radiated from the ship is a key part of its ability to detect submarines. Here we take an overview of this very technical subject.At more than £1Billion each, the Type 26 is a very expensive frigate, a significant part of that cost is driven by the need for stealth. Noise reduction is achieved by a combination of engineering solutions than include hull shaping, internal pipework design and securing equipment throughout the ship on shock and vibration-resistant mountings. But by far the greatest challenge is to ensure the engines and gear train can propel the ship quietly. The RN and British industry is already building from a position of experience and knowledge with the Type 23 frigates that set a new benchmark for warship stealth when they were introduced in the early 1990s. Type 26 frigate propulsion system(Schematic - not to scale)Diesel generatorReduction gearboxReduction gearboxSplittergearboxSSS clutchInduction motorInduction motorThrust blockStern tubeShaftShaft bracketShaft bracketPropellorPropellorShaftThrust blockStern tubeSSS clutchDiesel generatorDiesel generatorMT30 Gas turbineDiesel generator

A combination of gas turbines for higher speed and diesel generators (DG) driving electric motors is the preferred propulsion system for the Type 23, Type 45, QEC aircraft carriers and may other warships globally, although in significantly different configurations. The Type 26 introduces another variation in a Combined Diesel-Electric OR Gas Turbine (CODELOG) arrangement. Essentially there are two main operating modes. For higher speeds, a single Rolls Royce MT30 gas turbine (GT) drives the propellors directly through gearboxes. For cruising and slower speeds, up to four DGs provide power to two electric motors on the shaft line while the GT is de-clutched. Type 26 benefits from 30 years of advances in propulsion technology in two particular ways. The MT30 GT developed from the Trent aero-engine, has such power density that a single unit can propel the 6,900-tonne warship up to at least 28 knots on its own. (The CODELAG Type 23 requires two Spey GTs in combination with its motors to reach maximum speed). Modern motors are also much more power-dense than the those available when the Type 23 was designed. CODELOG Propulsion modes(Schematic - not to scale)Diesel-electric mode (0-20 knots)Gas turbine mode (20-28+ knots)Current from up to 4 diesel generators supplied to induction motors via power converterSingle Gas turbine drives both shafts through gearboxes

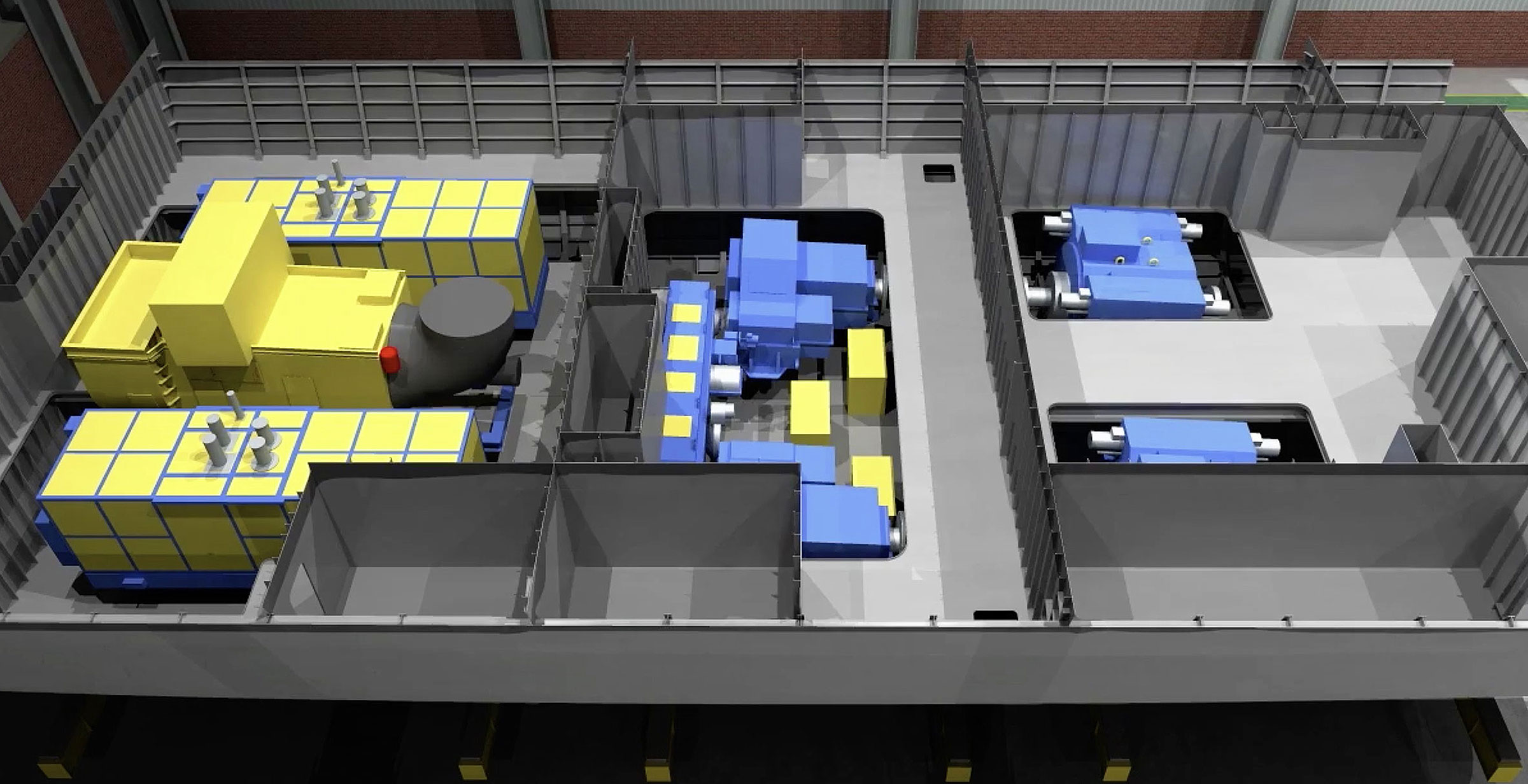

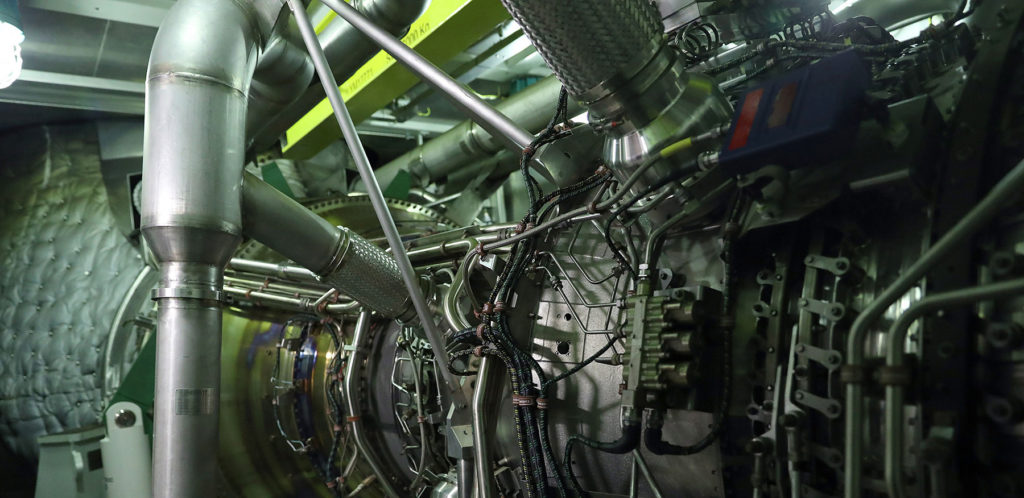

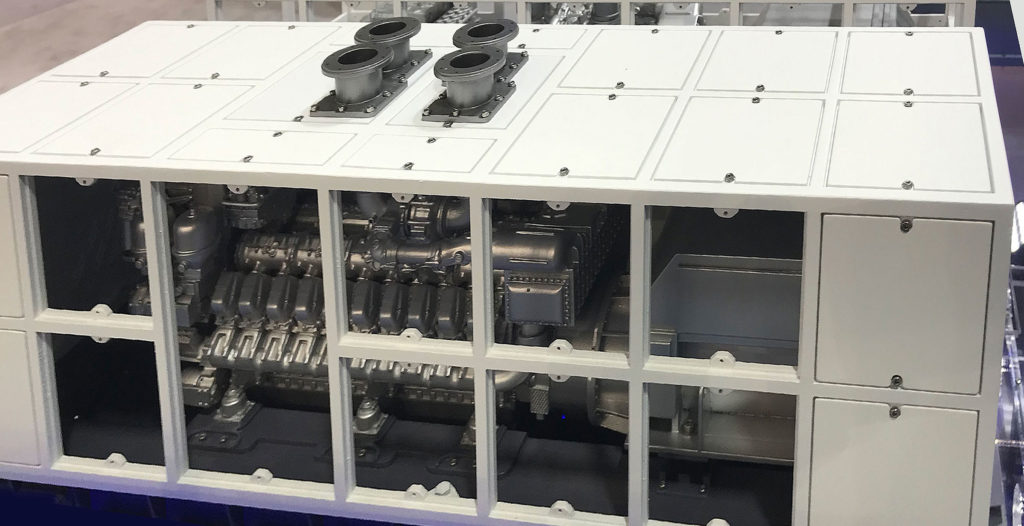

CGI showing the main machinery spaces of Type 26 under construction. MT30 Gas Turbine (Centre left) flanked by two diesel-generator sets. The gearboxes are in the centre compartment and the two induction motors in the aft compartment. (There are two further diesel generator sets not shown in this image).

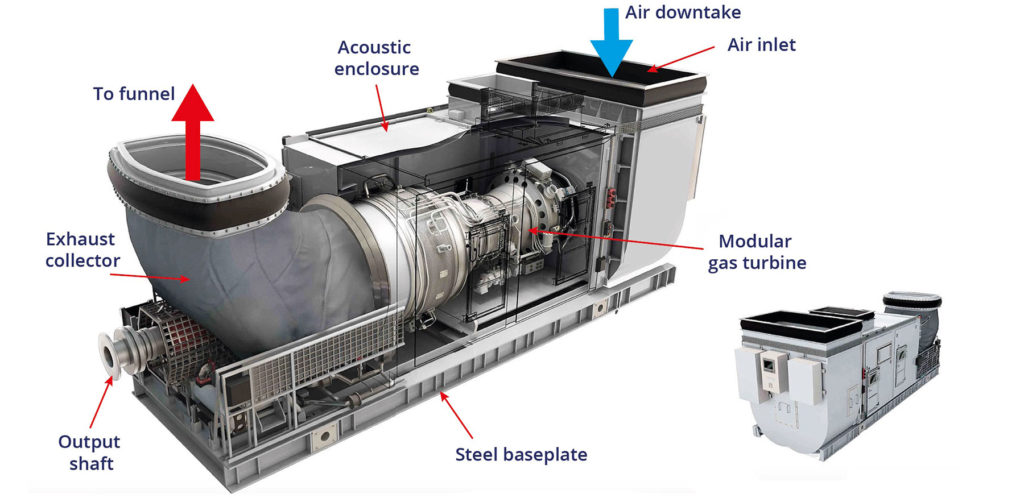

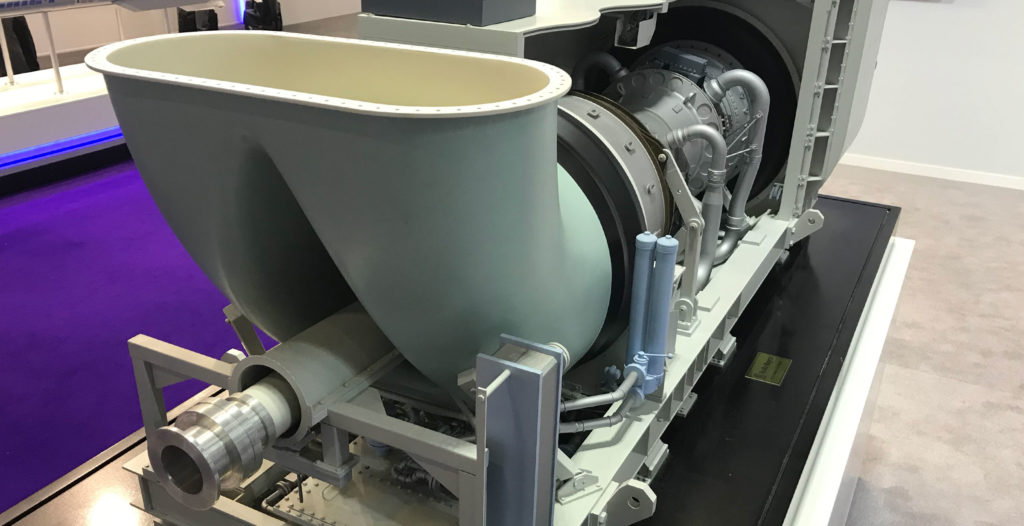

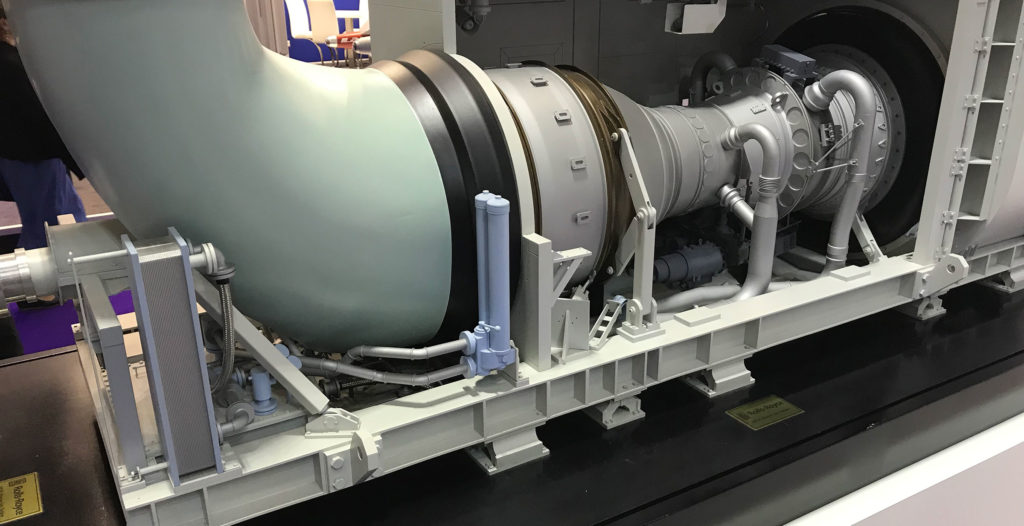

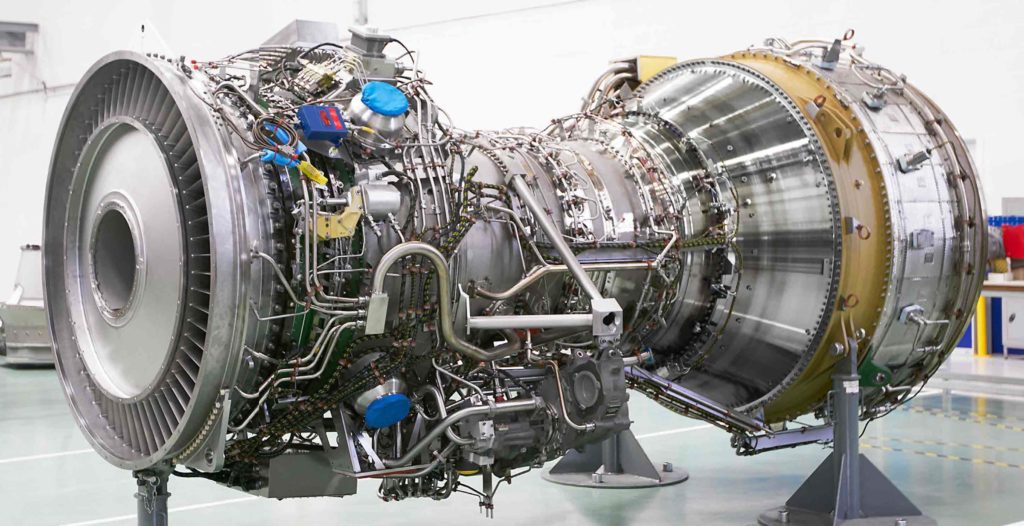

The mighty MT30

This is the most powerful marine turbine in the world and a modern British engineering and manufacturing success. The cores are manufactured in Derby and assembled in Bristol, the 50th example came off the production line this month. This engine is being adopted by the US, Japanese, Korea and Italian navies as well as the three Type 26 customers. Already at sea with the QEC aircraft carriers, the RN will have considerable experience with the engine before the Type 26 frigates enter service.The output power of the MT30 has been conservatively limited to 36MW but it has the potential to uprated by a further 10% which could be used to offset future displacement increases with the addition of new equipment. Built from proven components, incorporating the latest blade cooling technologies the turbine core is protectively coated to prevent corrosion from the salt-laden air of the marine environment. MT30 is a robust, four-stage power turbine based on the Trent 800 and meets all current emissions legislation without modification. It has been tested rigorously for 1,500 hours continuously in high (38°C) ambient air temperature. Resiliently mounted in an acoustic enclosure the turbine is designed to minimise vibration and radiated noise. The enclosure has Integral fire protection and has good access for maintainers. Designed to be operated remotely using an integrated digital control and monitoring system, the MT30 should require less than two man hours scheduled maintenance per week.

The DG workhorses

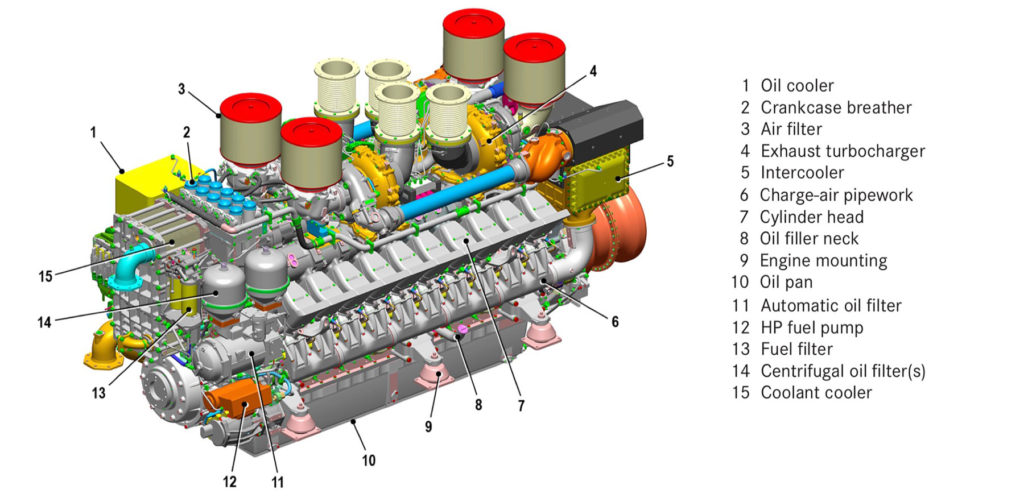

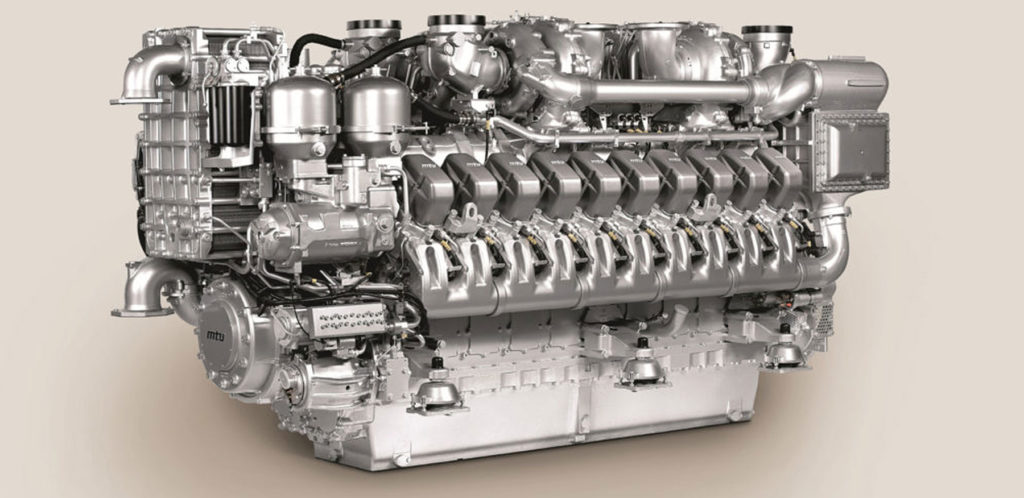

The four diesel-generator sets provide electrical power for slow speed and cruising using electric motors. Each DG set consist of an MTU 20-Cylinder 4000 M53B engine driving an alternator generating around 3MW. The DGs also supply the ‘hotel load’ to the rest of the ship. As increasingly powerful sensors and directed energy weapons are likely to be added in future, the power demands will increase and there is a significant reserve of extra power generation. The MTU brand is part of Rolls-Royce Power Systems and the engines are manufactured in Germany.

Diesel-electric drive is very fuel-efficient and the four sets can be selected sequentially, depending on the power needs so that they can be operated within their optimum range. This reduces wear on the engines and is very fuel-efficient. It also allows for redundancy in the case of failure or damage and engines can be taken offline for maintenance while at sea. Modern marine diesels are known for simplicity and reliability, MTU says the 4000 series only need a major overhaul after five years of operation. The ship is likely to spend much more time running in this mode than ‘sprinting’ on the more fuel-thirsty GT.

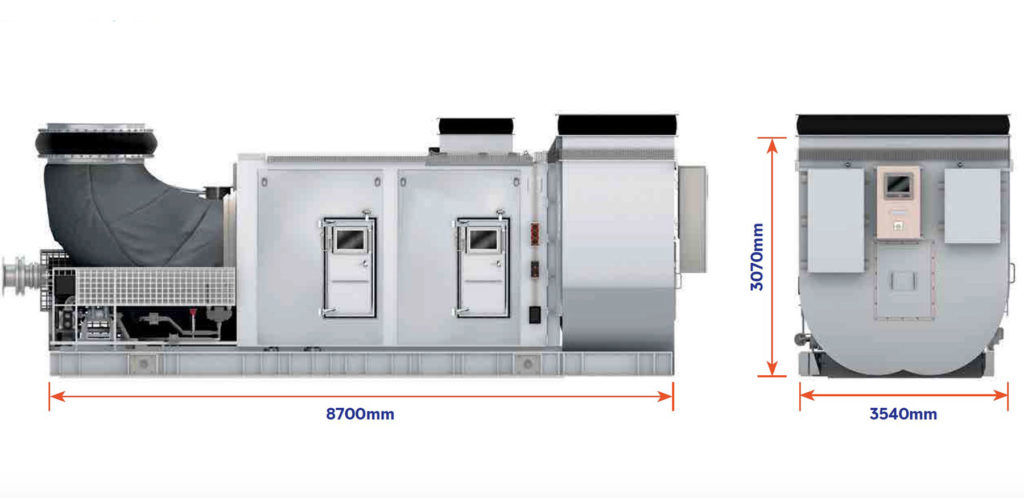

Like the GTs, the DG sets are completely contained in acoustic enclosures. The diesels are on their own resilient mounts inside and the whole enclosure is also on resident mounts to isolate it from the hull structure. It’s especially important that the DGs do not radiate noise as most submarine-hunting will take place at slow-medium speeds using the motors. Like the Type 23, the aft pair of DGs on the Type 26 are placed above the waterline to further reduce sound into the water.All new RN warships (starting with HMS Tamar) are to be built from the outset to meet the International Maritime Organization (IMO) III emissions directive. The diesels will be fitted with a Selective Catalytic Reduction (SCR) exhaust after-treatment system to neutralise nitrogen oxide emissions. It is also likely there are exhaust cooling systems installed in the uptakes and funnels to reduce the ship’s infrared signature.

Happy motoring

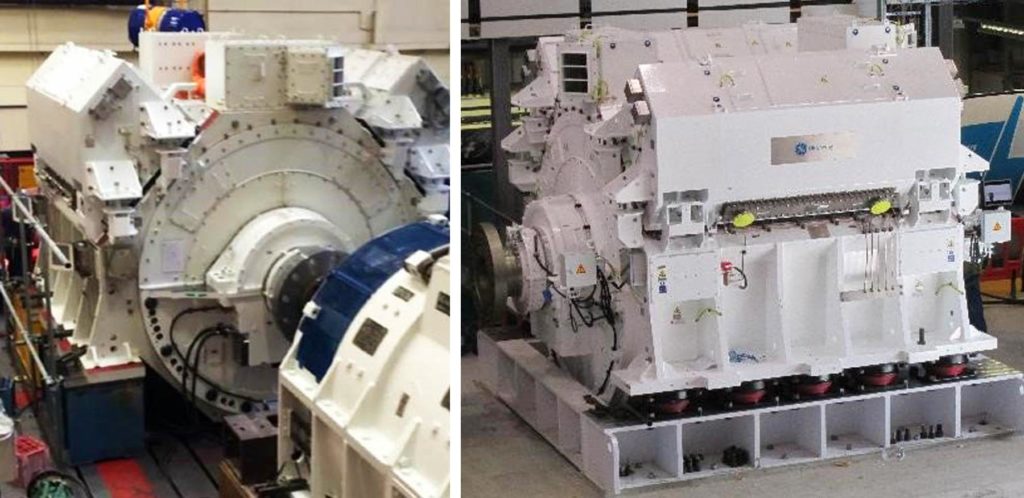

GE Marine manufactures the specialised Advanced Induction Motors (AIM) that propel the Type 26. They are manufactured in very specialist facilities with great care and precision to avoid vibration and to be shock resistant. The factory in Rugby was under threat of closure until recently, threatening the security of supply for all Type 26 customers. A campaign by concerned MPs, Unions and others resulted in the MoD placing an advanced order for the remaining 10 motors for the last 5 frigates. This saved the critical Rugby facility which will now specialise as a naval motor manufacturer. The site has a bright future with another 48 motors required for the 9 Australian and 15 Canadian ships, while other navies are also interested in buying this highly advanced British-made product.

The slow speed motors are placed directly on the shaft line to drive the propellors and are disconnected from the gearboxes and GT by Synchro-Self-Shifting (SSS) Clutches. This is an automatic clutch that disconnects when the speed of the main shaft being driven by the motor exceeds the of the input shaft driven by the GTs. Decoupling the gearbox further reduces noise in the ultra-quiet running state.

The motor speed is controlled by adjusting its frequency through an MV3000 marine converter made by GE. The fixed AC supply from the 4 alternators is converted to DC and changes are made to the waveform supplied to the motor using a technique called Pulse Width Modulation (PWM). The MV300 is widely used in industry but has been enhanced for naval requirements to be arc-proof, shock resistant and fitted with harmonic filters and power electronics to maintain current quality to avoid vibration in the motors. This builds on some of the technology first installed on the Type 45 destroyers (The root cause of the Type 45 propulsion problems was the WR21 gas turbines and not the electrical system).

Finding top gear

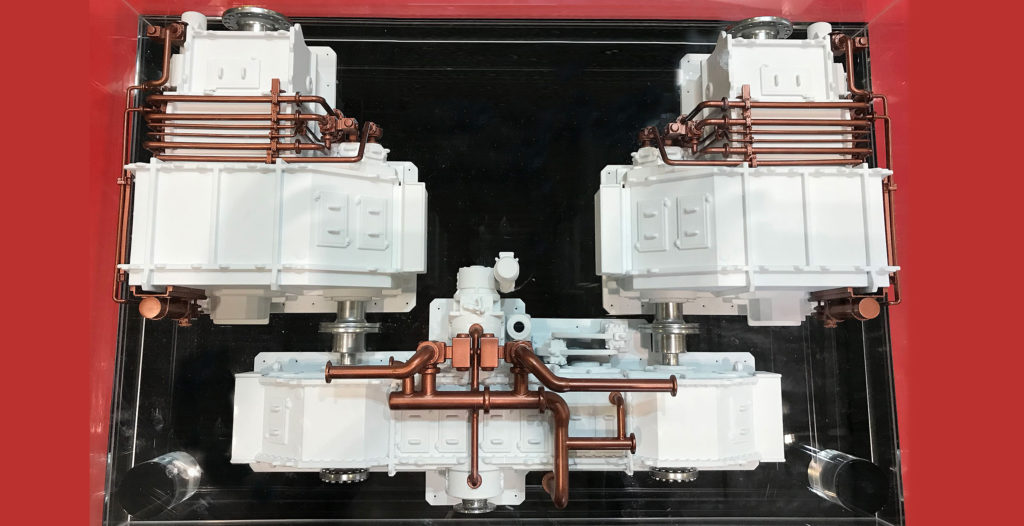

The gear train has been developed by David Brown Santaslo, especially for the Type 26 frigate. The company describes it as “the quietest ship gearbox in the world” and draws on decades of experience and silencing technology used in submarine gearing. The gear train consists of a splitter gearbox and two reduction gearboxes built to the highest standards to minimise transmission inaccuracies that are a source of vibration. The largest gears are around 3m in diameter but the gear teeth are machined to very fine tolerances measured in microns. The effort devoted to ensuring the gear train is of such high quality indicates that even at higher speeds, when propelled by the GT, the Type 26 will still be a quiet ship able to rapidly close the range on a submarine without detection.

DBS have constructed a dedicated Marine Gearing Assembly & Test Facility at their Huddersfield plant. This testbed replicates the gear train installed on the ship and is able to run the gearboxes up to full speed and with a full load. Each set that is manufactured will be tested on the rig before delivery. Once the gearboxes have been installed they are intended to last for the life of the ship and it is critical that there is full confidence in their quality and reliability.

Since the propulsion system has to be fitted in the hull during the early stages of construction, many of the elements are now mature, having been in development for many years and orders for ‘long lead items’ for first 3 ships were placed in 2015. Some equipment has already been delivered to the shipyard and is in the process of being installed onboard the lead vessel, HMS Glasgow. The weapon and sensors fitted to the Australian and Canadian ships will vary considerably but they will share the same propulsion system. This benefits the manufacturers who can look forward to sustained orders over many years. Commonality will reduce the unit cost for the customers who can also share training, logistic and operational experience. Besides the employment, skills and local economic benefit, industry can also invest in further research and development and in some cases, the Type 26 project is cementing their expertise as world leaders, attracting further export opportunities.

This article only skims the surface of the engineering complexity involved but indicates the extraordinary expense and effort needed to construct an ultra-quiet ship. Crew training, tactical skill, environmental conditions and the quality of the adversary are all important in successfully detecting and prosecuting submarines, but with the Type 26 the RN, RAN and RCN will have the best possible platform for the job.

All rights: Save the Royal Navy

Comments on Powering the stealthy submarine hunter – Type 26 frigate propulsion system in focus